3-D Printing

‘Exciting’ doesn’t even begin to describe it. It looks like something out of a Star Trek movie. It’s here, it’s now, and it’s happening and it has the potential to change our very way of life. I think it’s safe to say, that the future, has arrived.

Gone are the days when those big old clunky printers used to take more than a minute to print on a single piece of paper. Due to recent advances, laser printers have become possible, and it barely takes a second to print on a piece of paper.

What if I told you that one could now print the very piece of paper that you print on!?

“Impossible”, you might say. This is when I beg to differ. This is when my article changes your perspective.

What is 3-D Printing, exactly?

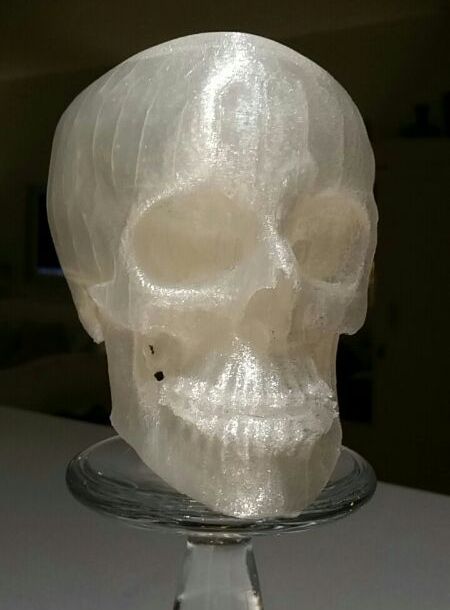

I must recall something about the printers we use now. They print ON paper. So it is pretty much Two Dimensional. Printing a Three Dimensional object essentially means that you are creating something similar to molding something, except that here, there is no mould. The printer gets the design of a 3-D model to be printed from an STL file, created using one of the softwares available for this purpose. It proceeds to print the 3-D component based on the STL file.

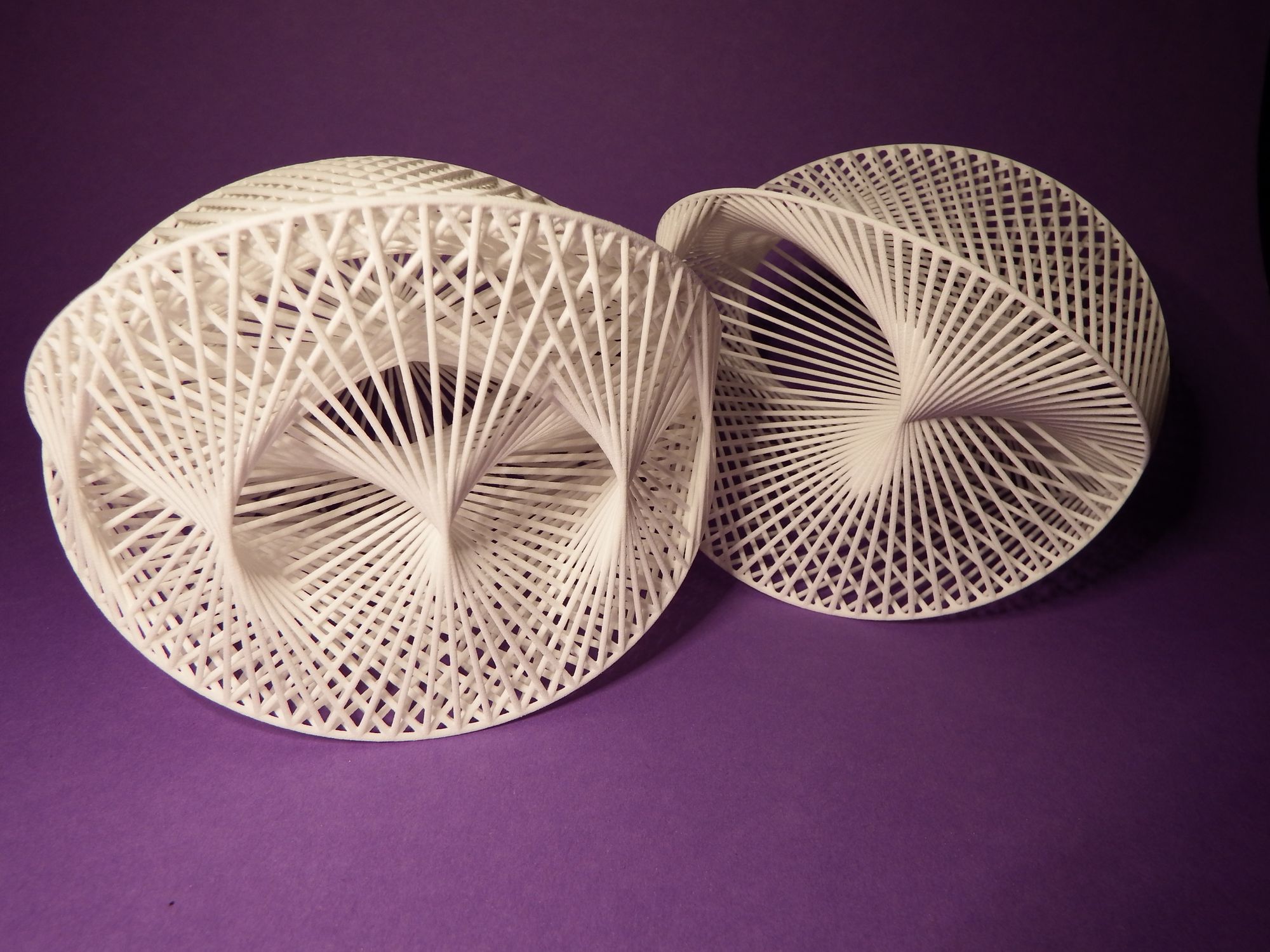

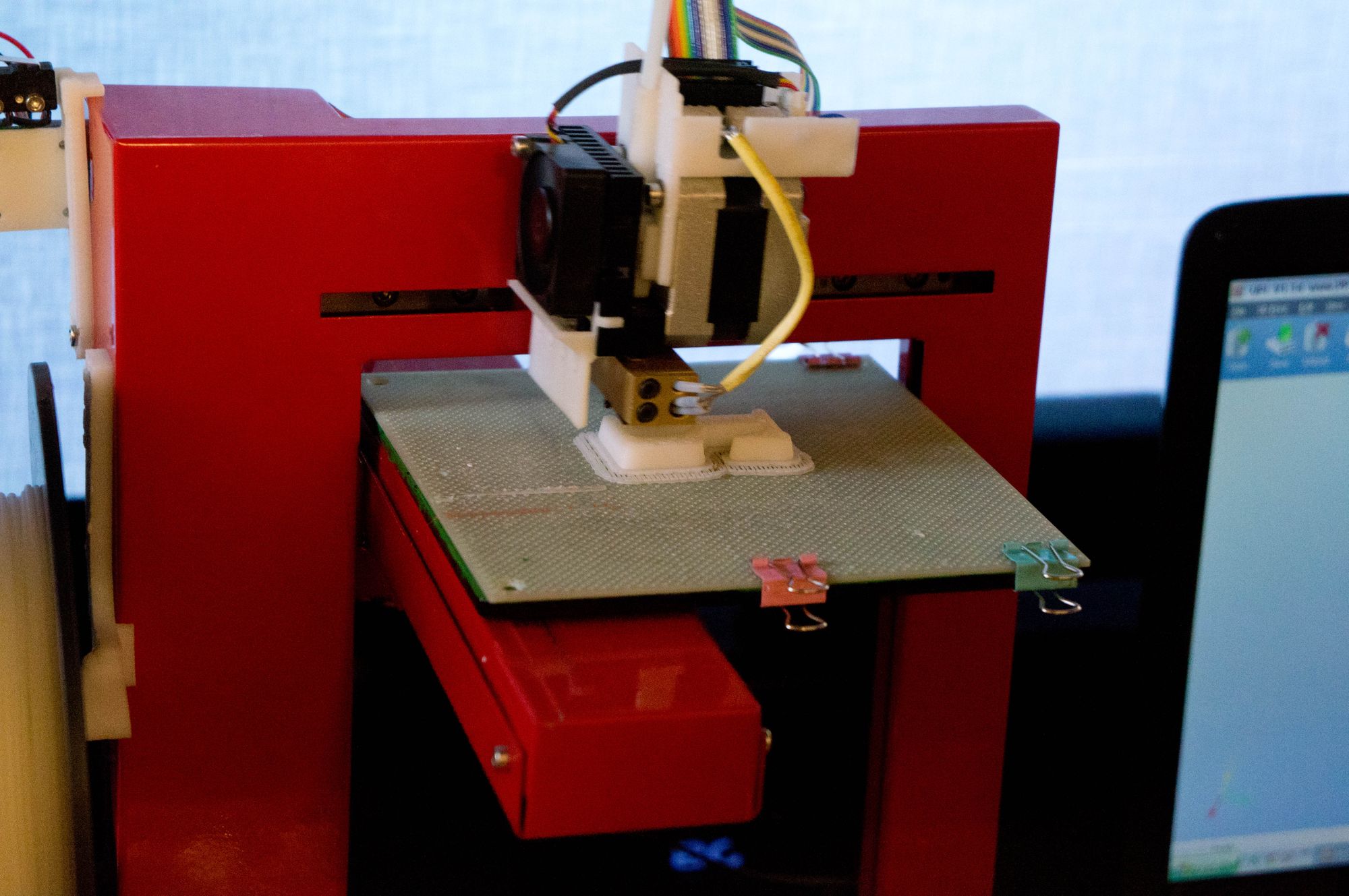

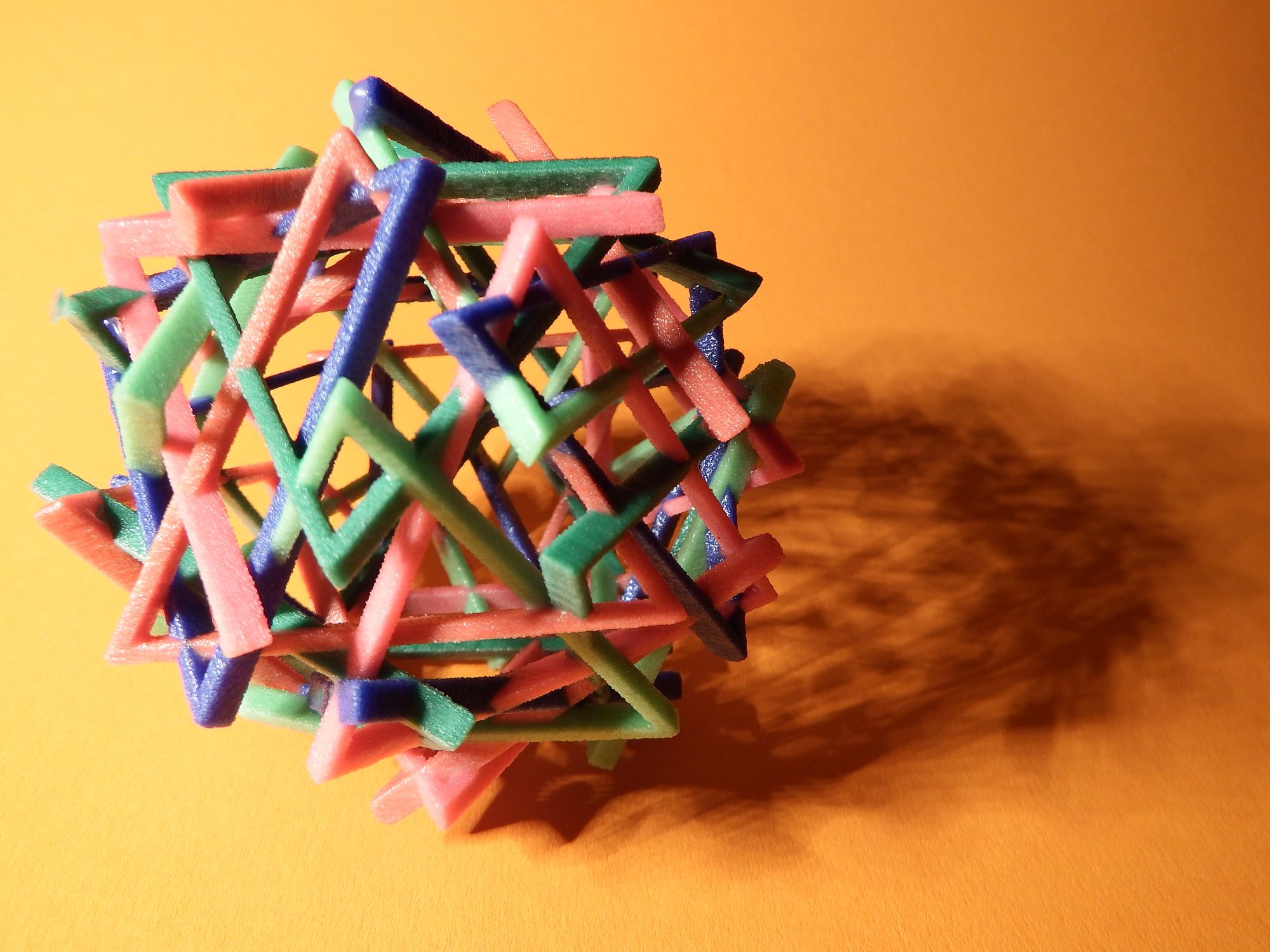

Advances in robotics have made possible the creation of robots that lay down successive layers of liquid, powder, paper or sheet material to build the model from a series of cross sections. These layers, which correspond to the virtual cross sections from the CAD model, are joined or automatically fused to create the final shape. The primary advantage of this technique is its ability to create almost any shape or geometric feature. Several projects and companies are making efforts to develop affordable 3D printers for home desktop use. Much of this work has been driven by and targeted at DIY(Do-It-Yourself) (enthusiast) early adopter communities.

RepRap is one of the longest running projects in the desktop category. The RepRap project aims to produce a Free and Open Source Hardware (FOSH) and a 3D printer whose full specifications are released under the General Public License and which is capable of replicating itself by printing many of its own (plastic) parts to create more machines! RepRaps have already been shown to be able to print circuit boards and metal parts.

“The only real limits are the ones you envision yourself having in your mind”-Arnold Schwarzenegger

The quote seems to apply for 3-D printing seamlessly. The applications of 3-D printing are limited only by your creativity and imaginative thinking. Its applications range anywhere from Bio-printing, i.e. having layers of living cells deposited onto a gel medium or sugar matrix and slowly built up to form three-dimensional structures and using these printed valves or organs as a possible replacement option for patients to printing clothing , eye-wear and even rocket engines. As a matter of fact, a rocket engine has already been 3-D printed using an alloy of nickel and iron.

When I say ,"The future has already arrived”, it looks all sparkly. Unfortunately, there are two sides to this coin too. In 2012, the US-based group Defense Distributed disclosed plans to “design a working plastic gun that could be downloaded and reproduced by anybody with a 3D printer. Defense Distributed has also designed a 3D printable AR-15 type rifle lower receiver (capable of lasting more than 650 rounds) and a 30 round M16 magazine. Soon after Defense Distributed succeeded in designing the first working blueprint to produce a plastic gun with a 3D printer in May 2013, the United States Department of State demanded that they remove the instructions from their website.

But their efforts were in vain. Even though these printable models were taken off the internet, they are still available through some sites like Piratebay, and the models are already out into the hands of people who do not understand the consequences. I think it is fair enough to say that this does not bode well at all.

Once these 3-D printers become hugely popular- which is seemingly a certainty- and industries begin employing these techniques in manufacturing, there is no worse predicament than that millions of jobs in assembling products will be cut. “Why assemble the product from pieces when you can print a stronger, lighter one from a 3-D model?” the companies might argue.

At the time of writing this article,Amazon has launched a new store for 3D-printed goods, which include items that can be customized to change their size, color, material and even aspects of their design. The store covers a range of types of products, including jewelry, electronics, toys and games, home decor and kitchen supplies.

As is the case with many of the technologies invented by man, this one too has its brighter and darker sides. It all depends on you, the “Human” quotient to decide how you will use it.