The Wondrous Tool that is Product Lifecycle Management

THE BRIDGE brings to the readers the collective experience of one of our alumni in “Techniques of Manufacturing’’ during the 2015 Alumni Congress

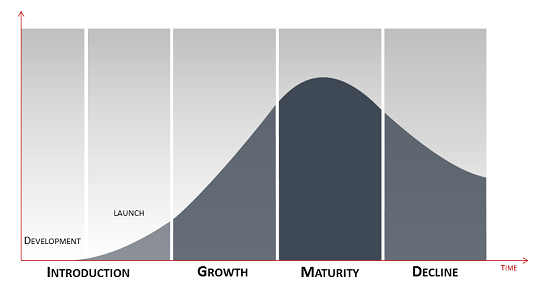

Every single entity on earth is bound to a cycle of some kind. It has an origin and an end. The duration in between depends both on their purpose and also the collateral damage encountered on the way. Humans and living organisms are well known to be entitled to a limited lifespan. It does not stop with living things, but is also applicable to materialistic and articulate things.

It is, therefore, of no peculiar nature when one’s interest in increasing, sustaining, improving – or to put it efficiently – managing a product’s life is considered. This desperate need, thus, led to the creation of a powerful tool, which is known to us as, Product Life cycle Management (PLM).

Graduating out of PSG College of Technology with a Master’s degree in Product Design and Commerce (M.E PDC) in 2008, MR.RAMSHANKAR SOMASUNDARAM, joined the ZF Wind Power Technology and is now seated as the Assistant Manager of its PLM division in Coimbatore. His predominant domain of work lies in designing turbines by CAD practices. He did his part in sharing his expertise with the students and faculty of PSG Tech as did so many alumni, on the Alumni Congress 15’ held on the 3rd of January, 2015. He made notable emphasis on the growing trend, potential improvements and research scopes that lie hidden in PLM.

A Little Walk-through:

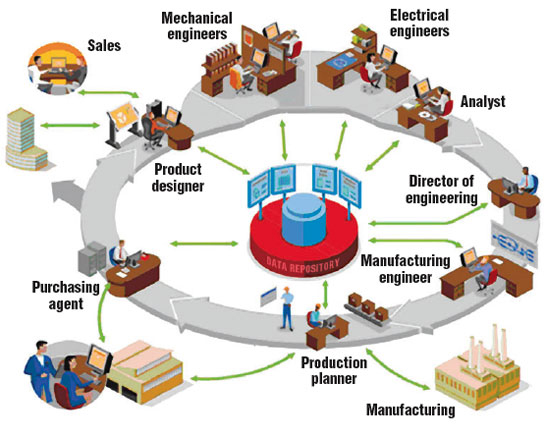

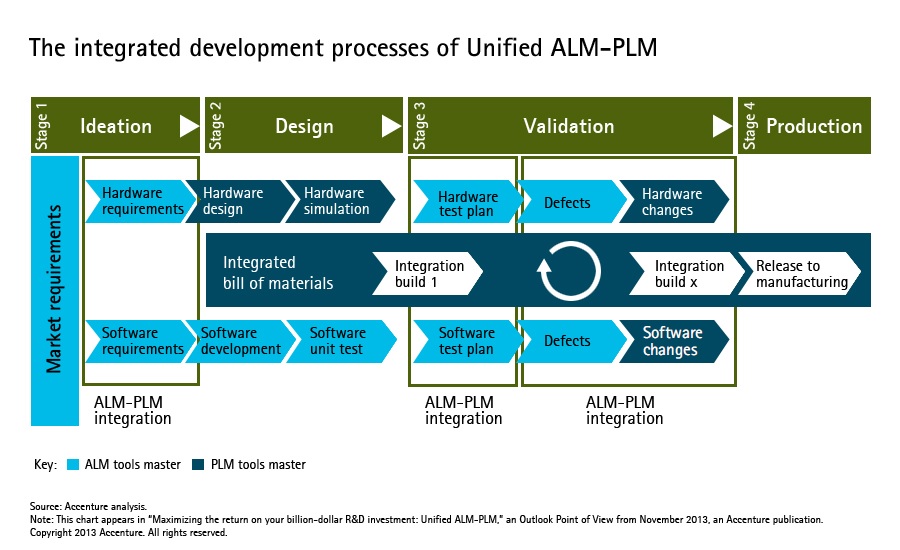

Product Life cycle Management is an established, yet a budding system, created to effectively manage the communication and information transfer between customers, design and manufacturing engineers, and finally marketing personnel. Due to growing preference for concurrent design approach over over-the-wall traditional approach, PLM is being made an integral part of a company’s infrastructure. By keeping all the information stored in a central database, influenced by various departments and people, PLM serves as the tool to manage the entire life cycle of a product, beginning right from the stage of conceptualization to manufacturing and disposing of such goods.

Present State of PLM:

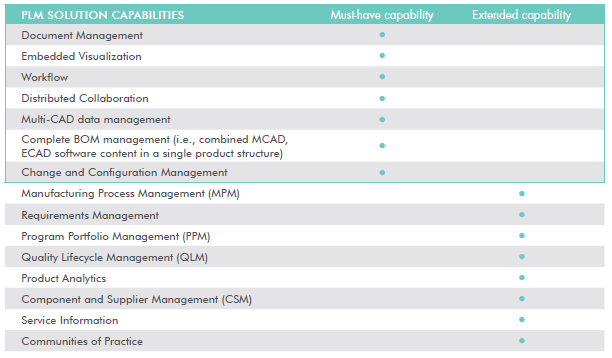

Back to our speaker, he highlighted the must-have and like-to-have features of a PLM system as could be seen below. This totals for new innovation and also their improvements through solid documenting; as it can be seen, some basic essential features like integrability of multiple CAD packages, embedded 3D visualization, workflow management and data management. Some add-on like standalone rendering and modeling tool, customer service management and other things would also increase their efficiency. Insights into upcoming technologies like interactive e-manuals and database management capabilities of CAD system are also provided. This is certainly interesting, because who doesn’t want a mechanical or electronic system to explain itself any of its functions rather than flipping through the hard printed, boring bulky manual.

Getting back to present, CAD system and drawings, and various simulation data continue to be integral parts of PLM. It is remarkable to note that the PLM, when first incepted, reduced the development cost to a record of 50%. With virtual prototyping on its spree, prototyping is becoming cheaper and faster every year and this feature among many others is what makes PLM more attractive. One such notable event is the manufacturing of Boeing 777 plane without a prototype, relying only on the simulation of CAD model. It did prove to be a technological milestone in modern manufacturing. Specifically tailored PLM solutions for specific industries have started appearing in the market for the same reason.

Propelling Technology Forward:

The more complex the product, more beneficial PLM becomes

In this concordant approach, everyone in a firm has a role to play in the design process. The degree of application of PLM depends upon the complexity of the product. One cannot see much use for PLM in the production of a bottle, while one cannot think the same for a spacecraft and airplanes. Thus, PLM enables us to stand on giant’s shoulders while innovating, instead of starting from scratch. Next time when we see any new innovative improvement in any product, we may as well recognize the role played by PLM in the design process along with its ingenuity. We must really thank our college for providing this platform and MR. RAMSHANKAR SOMASUNDARAM for using such, to share his experiences.